Walter's solid carbide drill for peak performance in aluminum holemaking

The new DC166 Supreme solid carbide drill from Walter has been specially developed for machining aluminum and other ISO N workpiece group materials, such as copper, brass and bronze.

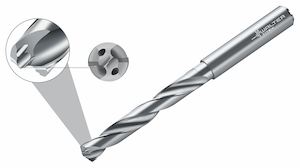

The drill with internal coolant features optimized point geometry creating a “coolant pocket” that provides more space for coolant flow resulting in better chip evacuation. In addition, the patent-pending web design results in sharper cutting action that prevents built-up edge and enhances chip removal.

The drill with internal coolant features optimized point geometry creating a “coolant pocket” that provides more space for coolant flow resulting in better chip evacuation. In addition, the patent-pending web design results in sharper cutting action that prevents built-up edge and enhances chip removal.

All the key surface on the drill—flutes, land and flank faces—are polished. Polishing reduces friction and prevents adhesion (built up edge) when drilling highly gummy material, which extends tool life and increases process reliability and hole quality.

The advanced drill design facilitates exceptionally high cutting speeds in conjunction with exceptional holemaking quality, particularly regarding hole roundness and the quality of the surface finish. The carbide drill can be used with emulsion, oil and minimum quantity lubrication (MQL).

The standard DC166 Supreme is for drilling holes up to 5 × Dc in accordance with the DIN 6537 long standard. The drill is available from 0.118 to 0.472 in. (3 to 12 mm) in diameter. Walter also enables the tool to be ordered as a special for drilling up to 30 × Dc in a diameter range from 0.118 to 0.787 in. (3 to 20 mm) via the Walter Xpress Service with a maximum delivery time of two weeks.

The drill has a 140°-point angle and is made from the uncoated WJ30UU, K30F grade. The DC166 Supreme drill is targeted for all application areas that drill non-ferrous materials, especially the automotive and aviation industries, and general mechanical engineering.