AMADA WELD TECH to highlight technologies at The Battery Show

AMADA WELD TECH will promote its battery and EV welding technologies at The Battery Show, September 12-14, 2023, at the Suburban Collection Showplace in Novi, Michigan.

On display in Booth 2537 will be the WL-P300A laser processing workstation, and the UB-4000A linear DC welding power supply paired with the TL-188B-EZ weld head and WM-200A IIoT-ready networked resistance weld monitor.

On display in Booth 2537 will be the WL-P300A laser processing workstation, and the UB-4000A linear DC welding power supply paired with the TL-188B-EZ weld head and WM-200A IIoT-ready networked resistance weld monitor.

WL-P300A is a Class 1 laser processing workstation optimized for marking on a range of metals (CRS, Copper, and Aluminum). Integrated with a IR fiber laser, it is ideal for making permanent, machine-readable marks on a variety of materials. The laser may also be used for welding of small components and has proven to connect battery tab to cylindrical Li-ion cells. Standard options include an XY table, rotary stage, cover gas module, fume extraction, bar code reader, and camera systems to tailor the machine to your specific processing needs.

The UB-4000A is a 200-4000 Amp linear DC resistance welding control that features four feedback modes, precise waveform control, and fast rise time. Weld energy may be programmed in current, voltage, power, or V-A in increments as short as 0.1 milliseconds. The power supply will be paired with the TL-188B-EZ pneumatic weld head, which operates at speeds exceeding 3600 welds per hour. This precise, low-inertia, force-fired weld head has a narrow vertical profile that exerts 5 to 100 lb (22-445 N) of force.

Complementary to the resistance welding system will be a live demonstration of the new WM-200A IIoT-ready, networked monitor. The monitor will collect high-resolution waveform data from the UB-4000A/TL-188B-EZ, which can be used for instantaneous comparison of good/bad signals, for statistical analysis of the process, and provide a means for manufacturing traceability. AMADA WELD TECH will also show a range of handheld and desktop weld process monitoring solutions to aid in production.

AMADA WELD TECH announces increased production and support for critical manufacturing applications for the battery industry

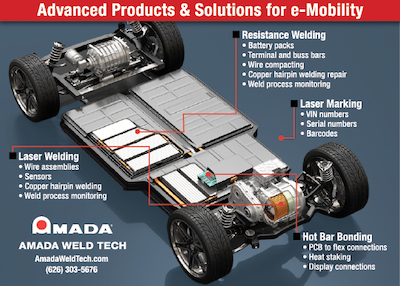

AMADA WELD TECH also announces the availability of the Jupiter series of modular systems for precision joining, available for laser welding, laser marking, resistance welding, micro arc welding, and hot bar bonding applications in the battery industry. Jupiter modular systems can be equipped with all joining process modules available from AMADA WELD TECH to provide solutions to customers within the battery industry.

With the Jupiter series, customers purchase an automation platform from a global joining equipment leader and receive intensive process development support in AMADA WELD TECH application development centers.

Joint early stage process development in AMADA WELD TECH labs ensures that customers receive the ideal system solution for years of high-quality production. Any welding, soldering, bonding, brazing, laser micromachining, and laser marking application can be handled by equipment in the Jupiter series.

The Jupiter modular system platform is a flexible system that comes in four sizes, so it is adaptable to specific production requirements. The stable platform enables connections of very high quality and accuracy. The modular design is configurable to fit all process components and modules. The Jupiter models feature an ergonomic system design with high quality components, designed for 24/7 continuous production. All models are equipped with a human-machine interface (HMI) with touchscreen for easy programming and standard safety features.

Control systems, based upon a programmable logic controller (PLC) or industrial PC, collect all available process parameters and process data into one control system. The data can be stored in local and remote storage areas, all engineered to seamlessly integrate with an Industry 4.0 factory concept.

Optional features for the Jupiter systems include a combustion suppression unit (CSU) for battery pack welding; a transport system with two individual belts that can be configured for a wide range of product carriers, including transfer systems; an automatic cleaning station for electrodes and thermodes; a “Not OK” bin to separate products outside the control limits from those within control limits; and a range of water cooling options. Also available are upgraded data collection and traceability functionalities, including a barcode reader or a label printer; and interfaces for a variety of robotic systems.